Rotational molding, often decreased to help rotomolding, has developed into top producing way for creating substantial, long lasting plastic material parts. This particular revolutionary procedure is actually gaining energy throughout businesses like car, agriculture, mineral water storage space, plus much more due to its exceptional gains around alternative developing techniques. Here’vertisements the reason why Rotational Molding may be the go-to solution with regards to making considerable, tricky, as well as tailored cheap components.

Outstanding Power and also Toughness

Rotational molding presents unparalleled architectural sincerity for giant plastic-type material parts. Mainly because the task requires heating up plastic-type to develop hole parts within a mold with no seams, the idea brings about merchandise by using consistent thickness no poor points. Such as, normal water fish tanks, gasoline bins, in addition to playground equipment advantage greatly through this method due to the fact virtually any seams as well as knees and lower back may lead to breaking under stress or pressure. As a result rotational molding a great preference when strength and durability usually are critical.

Cost-Effective pertaining to Choices

One of the talked about great things about rotational molding is actually its flexibility. With minimal installation expenses as compared to injections as well as blow creating, suppliers can easily tailor-make moulds to fit particular job needs. Adjustments to styles are usually more rapidly as well as less expensive, which often is a large benefit when developing customized or perhaps limited-run parts. Additionally, with a lot fewer going components throughout the apparatus, detailed prices remain rather lower, causeing the a highly affordable selection for manufacturers.

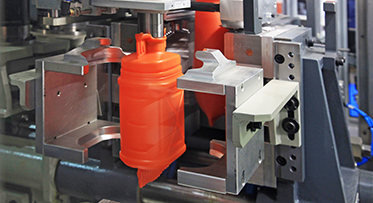

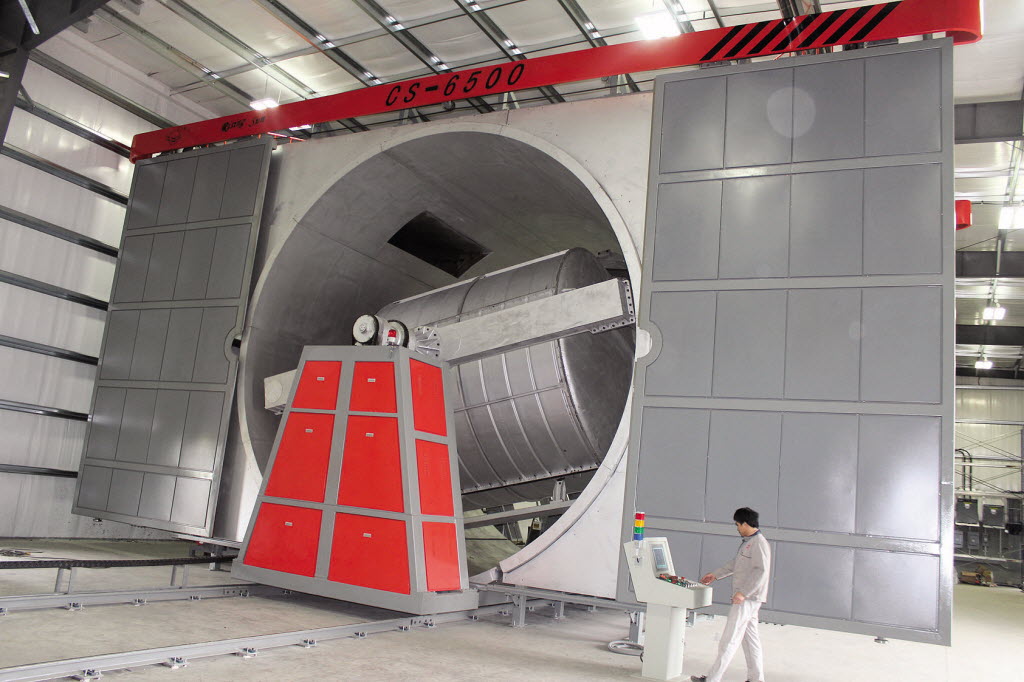

Well suited for Large as well as Complex Styles

Standard making techniques often struggle with generating substantial, elaborate shapes. This is why rotational molding excels. The procedure can certainly create enormous pieces just like kayaks, safe-keeping canisters, or maybe septic fish tanks without having compromising constitutionnel quality. The strategy assures even wall thicknesses and lets suppliers to develop delicate patterns or style details that other techniques will discover difficult or even harmful for reproduce.

Eco-Friendly and Useful

Rotational molding is remarkably eco-conscious. Accomplishing this produces small spend since excess plastic material can often be remade to get long run molds. Also, it can be works with a range of safe and sound in addition to recyclable products, like polyethylene, essentially the most extensively reprocessed plastics. This lines up together with the developing market pattern of deciding on ecological making alternatives, presenting businesses ways to decrease its environmentally friendly impression though giving high-quality products.

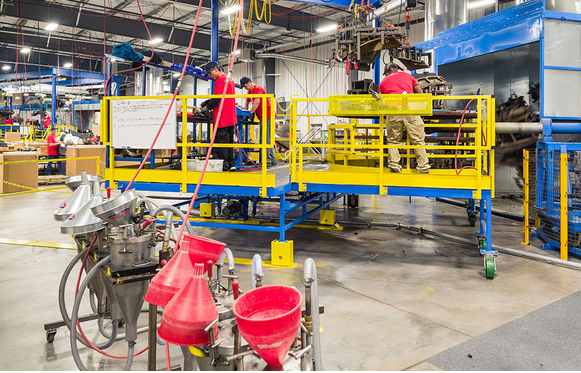

Any Tested Option Around Businesses

Coming from farming tanks for you to vehicle elements and even customized patio furniture, a flexibility connected with rotational molding features got the preferred developing approach all over different industries. Together with its ability to produce compact, tough, and cost-effective massive vinyl sections, this process is different seeing that the ideal solution regarding companies shopping to live ahead of time in the current cut-throat market.

Rotational creating is definitely more than just some sort of production process—it’s a game-changer intended for making high-quality large cheap sections when getting together with the strain regarding sturdiness, efficiency, plus customization. With regard to companies looking for current answers, this technique features unheard of advantages.